Motorcycle safety gear - a history of successive standards (source MotoCap)

- EN

- FR

(This post was automatically translated with www.DeepL.com/Translator)

I’m reprinting here, in French and slightly reworded, the short history of motorcycle protection standards for protective shells and pants and jackets as told by the main researchers and experts behind the MotoCAP protocol here: "A guide to designing and manufacturing motorcycle protective clothing" (PDF document written December 2022).

The authors are :

- Christopher Hurren, researcher Univ. of Deakin [Researchgate] ;

- Paul Varnsverry, dir. of certification body PVA-PPE [LinkedIn] ;

- Liz de Rome, researcher Univ. of Deakin [ResearchGate] [LinkedIn].

They focus on the voluntary (EN 13595 and NF EN 13595, 2 levels) then mandatory (EN 17092, 5 levels) standards for motorcycle pants and jackets. In Part 2, I take up their main criticisms of the latter.

They hardly mention the standards for motorcycle gloves and boots, EN 13594 and EN 13634. The one for gloves is systematically present, at least in France where CE gloves must be worn. The standard for boots seems to be less closely followed, given the number of boots sold in stores without a CE label.

(Note: the full document is a mine of information on the various materials and their resistance to different types of aggression, a must-read if you’re interested in the details).

I - History of the different standards

I.1 - 1994: The Cambridge Standard

The Cambridge Standard, developed by Dr Roderick Woods at Cambridge University in 1994, was the first published standard for motorcycle protective jackets and pants. The Standard is based on four levels of impact risk that were identified by mapping the distribution of crashed riders’ injuries and clothing damage. Under this system, Zone 1 had the highest risk exposure and required protection from impact forces and abrasion damage; Zone 2 also had the highest exposure to abrasion but did not require impact protection; and Zones 3 and 4 had decreasing levels of abrasion risk and little impact risk, respectively.

I.2 - 1998: European standards for impact protectors

In 1998, the European Standards body – the European Committee for Standardization, known as CEN – published EN 1621-1:1998 for motorcyclists’ protective clothing against mechanical impact. Applying Wood’s four impact-risk zones, the European Standard required impact protectors to be in Zone 1 with the average maximum force transmission not to exceed 35kN. At the time of writing, the latest edition of this Standard is EN 1621:1:2012.

Additional elements have subsequently been added to the impact standard. These enable the measurement of motorcyclists’ back protectors (EN 1621-2:2014), chest protectors (EN 1621-3:2018) and inflatable protectors (EN 1621-4:2013). A further standard for electronically activated inflatable protectors was under preparation at the time of writing. All use the same testing equipment with variation in impact energy and impactor mandrel geometry. Compliance with the standards has been strong and has seen the development of protectors that are differentiated according to protection levels, thinness and flexibility.

I.3 - 2002/2012/2020: European standards for motorcycle riders’ jackets and pants

The Cambridge Standard became a model for the development of the European Standard EN 13595:2002 for jackets, pants and one- or two-piece suits for professional riders. While compliance was mandatory within Europe, it was not enforced, and the Standard was largely ignored by both the industry and the rider community.

In 2012, the French Government introduced a modified version of EN 13595 for “non-professional riders”, called the French Protocol (NF EN 13595), which reduced the requirements for abrasion, cut and tear resistance.

In 2020, the European Union released a new standard for motorcycle jackets and pants (EN 17092:2020). The new standard was supported by accompanying regulations making compliance mandatory and enforceable for manufacturers. It came into effect in April 2018. EN 17092:2020 applies specifically to on-road riding and has five levels of protection. It does not include the distinction between professional and non-professional (recreational) use, which was present in EN 13595. The main differences between EN 13595 and EN 17092 are the way in which abrasion resistance is tested, and the reduction from four to three impact risk zones.

A comparison of the two European standards and the MotoCAP program is given in Table 1.2. The European standards are further described below.

Table 1.2 Comparison of testing schemes and standards.

| Scheme | Risk zones | Abrasion | Seam strength | Cut | Impact | Tear | Thermal |

|---|---|---|---|---|---|---|---|

| EN 13595 | 4-zone system | Cambridge | Hydraulic burst | Impact cut | EN 1621 | ISO 4674:2016 | ISO 3377:2011 |

| EN 17092 | 3-zone system | Darmstadt | Tensile strength | Not assessed | EN 1621 | ISO 4674:2016 | ISO 3377:2011 |

| MotoCAP | 4-zone system | Cambridge | Hydraulic burst | Not assessed | EN 1621 | Not assessed | Thermal sweating hotplate |

I.3.a - 2002: EN 13595

EN 13595:2002 closely followed the test methods detailed in the Cambridge Standard and comprised measures of four key criteria: impact abrasion resistance; seams and fasteners burst strength; materials tear strength; and impact cut resistance.

It was published in four parts:

• EN 13595-1:2002 covers the general requirements for a garment to meet one of two performance levels (Level 1 and Level 2). • EN 13595-2:2002 details the impact abrasion test using the Cambridge (CAM) test machine. • EN 13595-3:2002 details the method for undertaking burst resistance of seams and fasters using a Mullen type hydraulic burst tester. • EN 13595-4:2002 details the method for determining impact cut resistance using a falling knife.

I.3.b - 2012: NF EN 13595 (French Protocol)

In 2012, the French Government introduced their revised version of EN 13595:2002, also known as the French Protocol. While still using the EN 13595:2002 test methods, the French Protocol reduced the abrasion, impact cut and tear resistance requirements for Zones 2 and 3. It also retained identical abrasion resistance requirements in Zone 1 for both performance levels (4.0s). The protocol changed the injury risk matrix to a three-zone system by combining Zones 2 and 3 and reassigning them to a moderate risk of abrasion. Garments certified to the French Protocol have two levels of protection that are often shown on garments using the French spelling for ‘level’, Niveau.

I.3.c - 2020: EN 17092

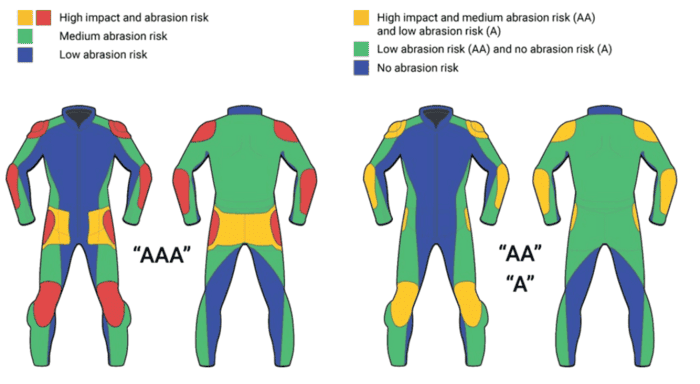

EN 17092 has five protection levels (AAA, AA, A, B and C). Classes AAA to A garments have the highest requirements for protection against all risks designated in the three-zone matrix, with Level A garments representing the lowest requirements.

In contrast, Class B and C garments have lower levels of protection required and do not offer protection against all the risk types identified in the three-zone matrix. Class B garments do not provide any impact protection; Class C garments only provide impact protection and are designed to be worn in combination with the other garments from the other Classes. Class C garments are also used in the off-road and motocross markets, where limb and upper-body impact protection is often provided by standalone garments.

The new standard is published in six parts. The first part, EN 17092-1:2020, details the methods for performing each of the tests, and provides details of the three-zone risk system. The remaining five parts correspond to five classes of protection (in descending order of test severity, EN 17092-2 to -6:2020: Classes AAA, AA, A, B and C respectively).

The method for testing impact abrasion resistance for EN 17092 was changed to the Darmstadt abrasion method (DAM). This machine is also referred to as an Advanced Abrasion Resistance Tester (AART). The DAM utilises a pass-fail criterion determined by the formation of a 5mm or greater hole. The test drops an undriven test sample onto a concrete abrasion surface at a set speed and allows it to slow to a stop under friction. Limited comparisons indicate that the DAM method is less aggressive than the CAM method: a 707rpm test speed pass on the DAM corresponds to a I.4-second abrasion time on the CAM.

The method for assessing seam strength in EN 17092 was changed from the hydraulic burst test in EN 13539-3:2002 to the tensile method still used for motorcycle gloves (EN 13594:2015). The method applies a tensile load to a 25mm seam segment and measures the force per millimetre required to rupture the seam. This method is directly comparable with the hydraulic burst method detailed in EN 13595-3:2002, with correction factors available to convert between the two tests. See Section 2.6 for a direct comparison of the two seam-strength methods.

The process for having garments certified to the European Standard requires manufacturers to supply a completed garment in a single size as a reference, along with flat sheets of the materials and seams used in the construction of the garment. It is those sheets that are tested for abrasion, seam strength and tear resistance. Test houses certified to provide EN 17092 certification of clothing include SATRA in the UK, CTC Groupe in France, Ricotest in Italy, TUV in Germany and IDIADA in Spain, although the official European Commission database of certification bodies accredited to test and certify motorcyclists’ clothing extends to a full list of more than 30 organisations.

II - Controversy: Analysis and criticism of standards EN 13595 and EN 17092

II.1 - Definition of injury risk zones

In motorcycle crashes, the frequency of different types of injury to each area of a rider’s body follows a well-documented pattern. Large-scale studies of rider injuries and evidence of impacts or damage to their clothing have been used to identify the key areas of risk to a rider. These areas have been used to define the location, type and level of protection required in protective clothing. The risk zone diagrams also allow for stretch and breathable panels to be incorporated in areas of the garment at lower risk of impact. There are two systems used for defining the injury risk to riders. The first is a four-zone risk diagram that is utilised by EN 13595 and MotoCAP. The second is a three-zone risk diagram that is utilised by EN 17092. The following section identifies each of the impact risk zoning systems.

II.1.a - EN 13595 : Four-zone injury risk diagram

The four-zone risk diagram is based on the relative risk of crash impacts and injury to different areas of the body. It was developed from crash and hospital injury studies by Roderick Woods. The four-zone system has been validated several times through crash research over many years. There are two mechanisms involved in protecting a rider’s body. The first mechanism provides impact energy attenuating measures in Zone 1 to reduce the risk of bruises, sprains, dislocations and fractures by absorbing and distributing the forces of direct impacts to those most exposed areas. The second mechanism provides protection from injuries to skin and tissue across all zones by use of materials and construction that are resistant to abrasion, impact cut, tearing or bursting.

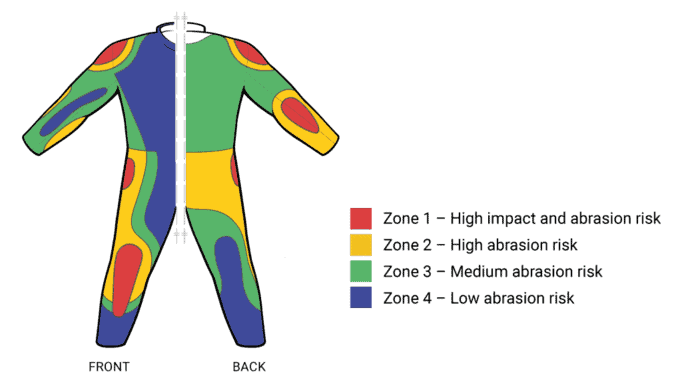

Figure 2.1: Four-zone injury risk diagram (EN 13595-1:2002).

The type and level of protection required in each zone are illustrated in Figure 2.1. They are:

- Zone 1: High risk of impact and abrasion injury

- Zone 2: High risk of abrasion injury

- Zone 3: Moderate risk of abrasion injury

- Zone 4: Low risk of abrasion injury.

The shoulders, elbows, hips and knees are classified as Zone 1, being the parts of a rider’s body most exposed to direct high impact and abrasive forces. Zone 2 encircles Zone 1, having a similarly high risk of abrasion, burst and cut damage but less risk of direct impacts to the key skeletal joints. Zones 3 and 4 require successively lower levels of protection from abrasion, burst and cut damage. The lower risk of Zones 3 and 4 allow for the use of stretch and ventilation to be placed within a garment to ensure that it is comfortable to use.

II.1.b - EN 17092 : Three-zone injury risk diagram

EN 17092-1:2020 was developed as a standard for the certification of non-professional riders’ clothing. While drawn from the four-zone risk system, the new standard was based on the assumption that injury risk was lower for non-professional riders. The new system developed was a three-zone system (Figure 2.2). Three zone templates are required for the new risk system. Class AAA garments have a section around the buttocks that defines an increased risk of abrasion injury, which is absent from the requirements for the lower performance classifications. Class A garments use the same risk template as Class AA, but do not require hip impact protection. An AAA-rated garment would be more likely to be worn by someone travelling at higher speeds, increasing their risk, whereas an A-rated garment is more likely to be worn in an urban environment at lower speeds, reducing the rider’s risk.

The rationale for a three-zone system is not strong when the published work validating the four-zone system is considered. The validation of the four-zone system was done on all riders, not just on professional riders, so it should be applicable for all riders. It is recommended that the four-zone system is followed for all clothing design. Designing to the four-zone system will provide the highest level of protection to riders; importantly, it will also easily satisfy all the requirements of the three-zone system as well as MotoCAP.

Figure 2.2: Three-zone injury risk diagram (EN 17092-1:2020).

Note: Class A garments do not require hip impact protection.

II.2 - Cut resistance

Cut resistance is the ability of a material to resist cutting when impacted by a sharp object. Cut resistance testing was part of the European Standard EN 13595-4:2002, which uses the impact cut method developed for butchers’ clothing. This method measures the depth of penetration of a sharpened blade into the test specimen when travelling at a velocity of either 2.0 or 2.8m/s.

It was added to reflect the conditions found on roads in certain parts of Europe where snow chains and studded winter tyres had eroded the sealant between individual pieces of aggregate and honed the aggregate itself to a sharp edge. Recent work at Deakin University has found that sharp aggregate surfaces on some dual-aggregate chip seals can induce cutting of clothing materials. EN 17092 does not measure cut resistance of motorcycle clothing materials.

II.3 - Burst resistance

Burst failure is the rupture of a garment on impact with an abrasive surface. In most cases, burst failure occurs at a seam or garment closure, as these tend to be the weaker parts of the garment. Burst failure occurs due to tensile loads that the abrasive surface and the movement of the rider’s body exert on the garment. As a material impacts the ground, it is gripped by the surface macrostructure. The rider’s forward momentum creates a tensile force into the clothing materials forward of the point of grip. In burst failure, this tensile force (grip loading) is high enough to rupture the seam, closure or fabric.

The downward impact speed, weight of the rider, speed of forward movement and stretch of the garment all have an influence on the propensity to burst. Higher grip is achieved when the force pushing the material into the road is high and the time available to achieve grip is long. The rider’s weight and the speed of downward impact both influence the level of grip by increasing the extent to which a material is pushed into the abrasive surface. The speed of forward movement and the level of stretch within a garment both influence the time that grip can occur before the maximum gripping force is achieved and the tensile force applied. Slower riding speeds allow for more grip to occur before the tensile load is applied and hence increase the risk of burst failure. Stretch fabrics allow for more grip to occur while they convert forward momentum into fabric stretch. They will have a higher grip level when the tensile load is applied than an equivalent-weight non-stretch material, increasing their propensity for burst failure.

(…)

Burst resistance can be measured by either a hydraulic burst or tensile test method. The use of a hydraulically inflated diaphragm to load seams is the better of the two methods, as seams are loaded in all directions during the test. Tensile testing, however, only loads the sample from one direction (i.e. perpendicular to seam) so is not as comprehensive as hydraulic burst testing. Hydraulic burst testing is also more suitable for measuring stretch materials than tensile testing, which lacks repeatability with stretch materials.

[Translator’s note : EN 13595 used a hydraulic burst test, EN 17092 uses a tensile test]